H2S Removal Requires Media and a Vessel

Renewable natural gas derived from biogas sources is a valuable and sustainable energy resource captured from landfills, digesters, or lagoons and conditioned to either be added to the gas grid or compressed for vehicle fuels. Before entering the pipeline, H2S and other contaminants must be removed to make the biogas safe and stable. The most common and effective way to remove H2S involves both a media that extracts the H2S and a vessel specially crafted to house the media, facilitating gas to flow evenly through the media bed with low pressure restriction.

Removing H2S at the forefront of the process is essential for the safety of transport and the convenience of removing other contaminants downstream. However, lead time on other vessels can range from six to twelve months, often requiring new engineering design work and significant on-site infrastructure construction. The wait time and necessary location upgrades can make vessel implementation expensive, challenging, and time-consuming. VAV units can easily be implemented in existing systems, so no time or money is wasted waiting on a traditional vessel.

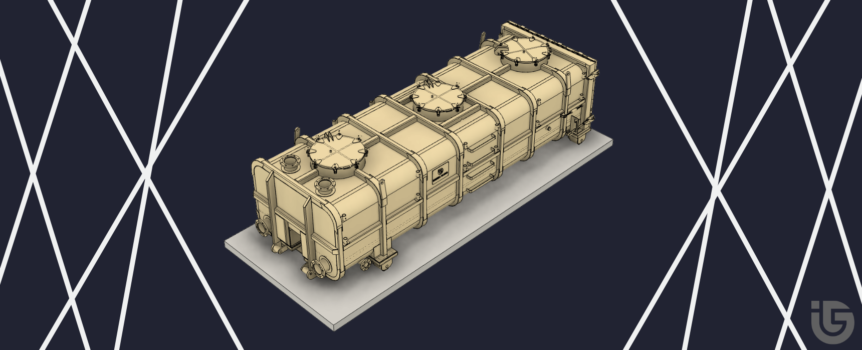

The Interra Global Vacuum Adsorption Vessel, or VAV, is crafted with site owners in mind. These units are portable and can be placed directly on dirt or gravel at a site. Deployment is rapid, and using a VAV is as easy as plug-and-play. Interra Global developed this H2S removal equipment to maximize media performance, especially when using FerroSorp® H2S removal media. In addition, VAVs are designed for gas to flow evenly through the entire bed and fully utilize the media.

Key features include:

- Transportable by roll-off truck or on a flatbed

- 3 large 36“ hinged manways for easy media filling & removal

- Hinged bulkhead door for easy clean-out

- Spent media can be dumped or vacuumed

- Can operate under vacuum or 5 psi positive pressure

- Engineered, built, & supported in the USA

- 440 ft3 media bed capacity (17,600 lb of FerroSorp®)

- Optional safety decking and fall protection package available

Interra Global has VAVs in stock for rapid deployment and ready to deliver to dairy, landfill, and food waste locations. Units are modular and scalable to meet your deployment needs or expanding capacity. Our engineering and support team are here to help you work through unique site specifications and ensure the VAV is right for your application. We’ll ensure that your vessel needs do not become the bottleneck to your project’s completion. Give us a call or send a quote request to get in touch with our team for rapid VAV deployment to your site.